PRODUCTS

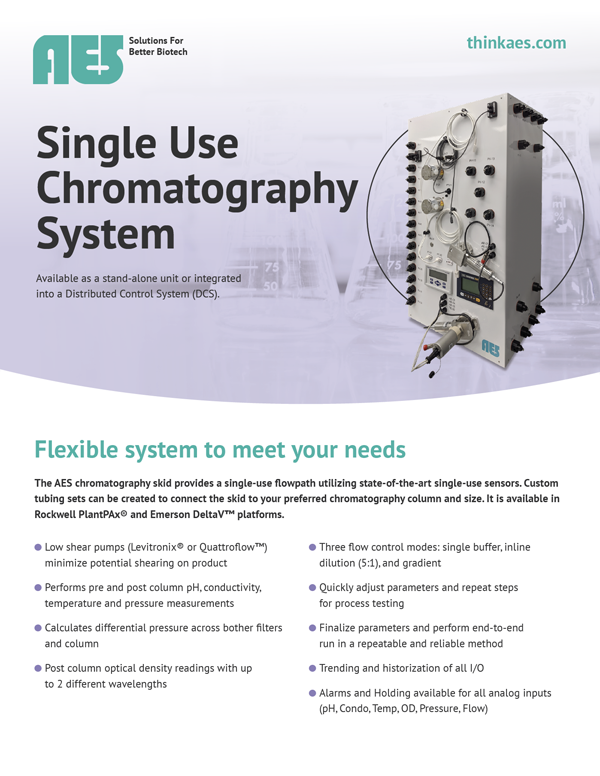

AES Single Use Chromatography System

Flexible system to meet your needs

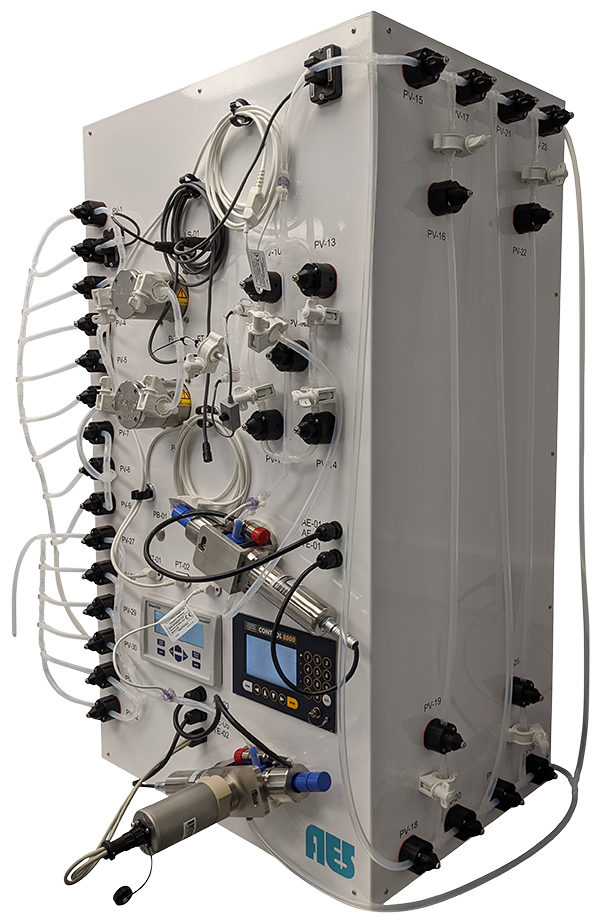

The AES chromatography skid is available as a stand-alone unit or integrated into a Distributed Control System (DCS). It provides a single-use flowpath utilizing state-of-the-art single-use sensors.

System features & benefits

- Low shear pumps (Levitronix® or Quattroflow™) minimize potential shearing on product

- Performs pre and post column pH, conductivity, temperature and pressure measurements

- Calculates differential pressure across both filters and column

- Post column optical density readings with up

to 2 different wavelengths - Three flow control modes: single buffer, inline dilution (5:1), and gradient

- Quickly adjust parameters and repeat steps

for process testing - Finalize parameters and perform end-to-end

run in a repeatable and reliable method - Trending and historization of all I/O

- Alarms and Holding available for all analog inputs (pH, Condo, Temp, OD, Pressure, Flow)

- Overview

- Tech Specs

- Literature

Customize to meet your needs

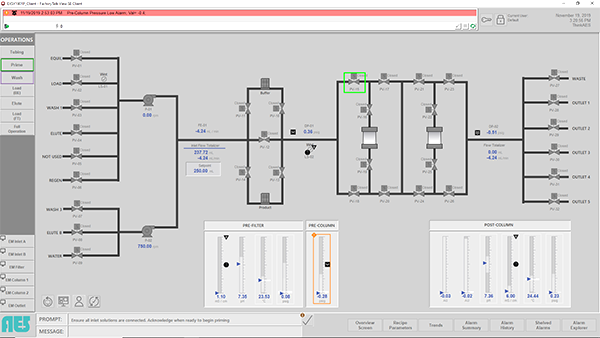

YOU keep control

The control layer creates a modular system that easily integrates with an existing distributed control system (DCS) or as the start of a new site DCS. The AES Chromatography System is available in Rockwell PlantPAx® and Emerson DeltaV™ platforms.

All online adjustments, historization and system information is presented remotely through your networked computer or local HMI. Control hardware and software are 21 CFR Part 11, GMP/GLP and ISA-88 compliant to satisfy regulatory requirements. Additionally, all control software code is transparent and open source, giving you the freedom to make modifications as needed.

Skid Specifications (0.25″ Version)

| Dimensions | 45.72 H 26 W x 18 D, inches |

| Column | Bed Height Range: 10-60 cm Column Inner Diameter Range: 2.5 – 8 cm Packed Column Volume Range: 20 – 1500mL |

| Flow Path Sizes | Choice of 1/8, 1/4, 1/2, 3/4, 1, and 1.5 inch sizes |

| Inlets | 8 inlets standard; up to 12 inlets possible |

| Outlets | 6 outlets standard: 1 waste and up to 5 fractions |

| Pressure | Up to 60 psig |

Control

| DCS | Rockwell PlantPAx® |

| Hardware protocol | Ethernet/IP |

| Interface | Windows®-based PC or HMI |

| Software standard | ISA-88.1 |

Process Instrumentation

Process instrumentation specifications shown below are based on 1/4˝ tubing. Specifications for pumps, flow, and valves may vary based on tubing size.

| Inlet Pumps | PSGDover Quattroflow Model: QF150SU Flow Range: 16 – 3000 mL/min (1-180 L/hr) Connections: ¼” TC Pump Head: QF15DISPP MOC: Polypropylene, TPE, EPDM |

| Valves | Accro Model 600 Solenoid Pinch Valve Model: 606CN-SDBN5-090-0375 Tubing Range: 0.250 – 0.375 inch OD (3.2 – 9.5mm) |

| Flow Sensors | Pendotech Single Use Ultrasonic Model: FM-LFS-06SU Measuring Range: 0 – 8000 mL/min MOC: Polypropylene Connections: ¼” Sanitary |

| Pressure Sensors | Pendotech Single Use Pressure Sensor Model: PREPS-N-025 Measuring Range: -7 – 75 psi (-0.48 – 5.2 bar) MOC: Polysulfone Connections: ¼” Hosebarb |

| Air Sensor | Pendotech Air in Tube Detector Model: AD-17 Tubing Range: 3/8” OD |

| pH | Optek pH Sensor PF12 Measuring Range: 2-12 pH |

| Conductivity | Optek Conductivity Sensor ACF60 Measuring Range: 0-150 mS/cm |

| Optical Density | Optek UV Sensor AF46 Wavelengths: 280/320 nm (Customizable) Measuring Range: 0-2 CU Path length: 2.5 mm |

Specifications subject to change without notice.

Windows® is a registered trademark of Microsoft Corp. DeltaV™ is a trademark of Emerson Process Management. PlantPAx® is a registered trademark of Rockwell Automation. Levitronix® is a registered trademark of Levitronix LLC. Quattroflow is a trademark of ALMATEC Maschinenbau GmbH