PRODUCTS

AES Bioreactor Cell Culture Systems

Ideal for a wide range of cell culture applications, including high cell density processes

The small-scale AES Bioreactor Cell Culture System provides an automated, controlled platform for the expansion of cell culture production systems within a glass reactor. The system is a re-useable and autoclavable solution for early stage research, product development and commercial applications.

System features & benefits

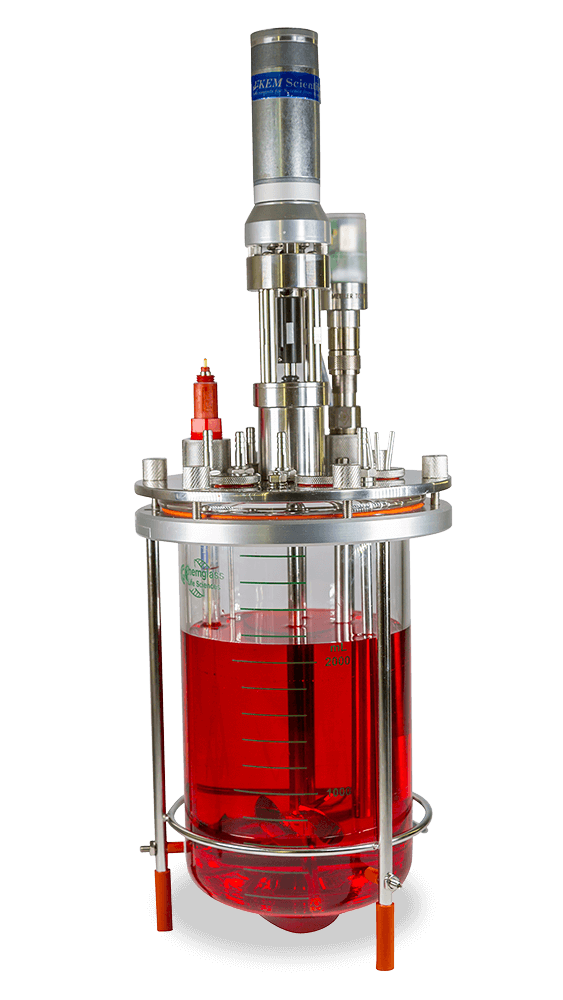

- Reusable, autoclavable glass reactor

- Stainless steel components and head plate for longer life

- GMP/GLP compliant to satisfy regulatory requirements

- 2L bioreactor standard for small-scale bioreactor system; can be configured with different bioreactor sizes to meet your needs

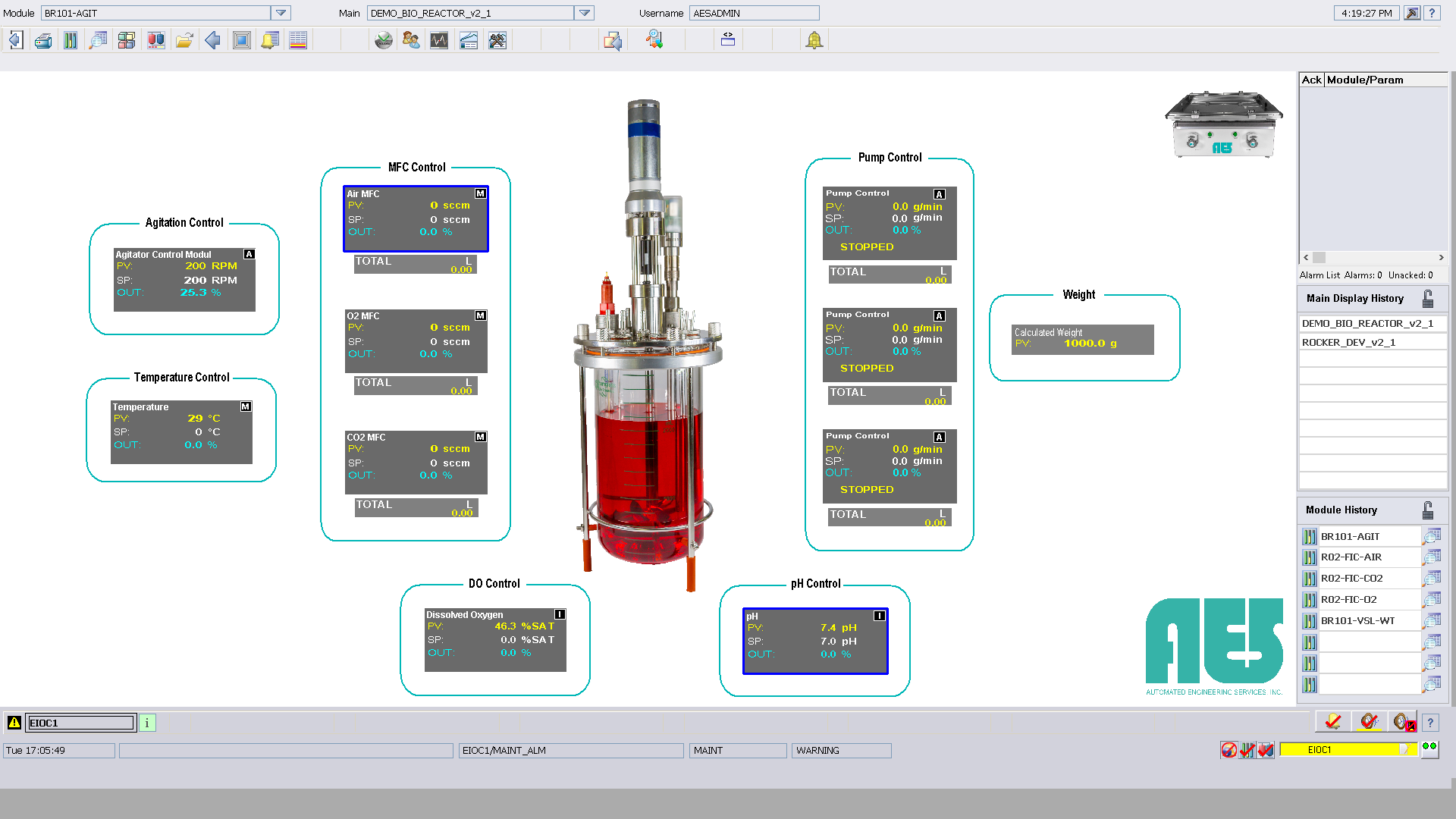

- Integrated pH and DO control and 4 gas MFC control enables adjustment of the gas environment inside the reactor to suit your application needs

- Industrial control system enables for remote monitoring and control

- Transparent, open source control software gives you the option to manage future system updates in house

- Integrated 4x pump system for additions

Compact system instrument footprint maximizes work space

- Overview

- Tech Specs

- Literature

System benefits

The system creates the ideal environment for a wide range of cell lines and organisms and supports high cell density processes. Typical applications include bacterial and mammalian product cell line systems. Bioreactors, available in sizes from 2L, can be used as a platform for solera, seed train, perfusion or N stage batch and fed-batch operations.

Space-saving design that’s easy to use

The system’s streamlined externally housed quad-pump saves you valuable work space whether in the lab or a commercial environment. And when part of an automated process, the industrial control layer enables remote process monitoring and control wherever network access is available. The control system’s intuitive user interface makes it easy for you to monitor and adjust all processes running on the AES Bioreactor Cell Culture System.

YOU keep control

The control layer creates a modular system that easily integrates with an existing distributed control system (DCS) or as the start of a new site DCS. All online adjustments, historization and system information is presented remotely through your networked computer or local HMI. Control hardware and software are 21 CFR Part 11, GMP/GLP and ISA-88 compliant to satisfy regulatory requirements. Additionally, all control software code is transparent and open source, giving you the freedom to make modifications as needed.

Vessel

| Total volume | 2100 mL |

| Working volume | 1800 mL |

| Internal diameter (glass reactor) | 105 mm |

| Overall height (glass reactor) | 246 mm |

Control

| DCS | Emerson DeltaV, DeltaV Discovery, PK Controller or Rockwell PlantPAX |

| Hardware protocol | Ethernet/IP, DeviceNet, Profibus (others available upon request) |

| Interface | Windows®-based PC or HMI |

| Software standard | ISA-88.1 |

Process Instrumentation

| Heat control | Single-sided, heating blanket |

| pH control | Mettler Toledo |

| DO control | Polarographic or Optical Mettler Toledo |

| Pump control | 3x integrated pumps for additions and harvest, Master Flex |

| Gas control | 3x MFCs |

| Temperature probe | PT100 RTD |

| Heat source | Relay controlled heating jacket |

| O2 | Brooks 2000 sccm |

| Mixed Air | Brooks 2000 sccm |

| CO2 | Brooks 2000 sccm |

| N2 | Brooks 2000 sccm *additional cost applies |

| Agitation | Direct Drive, 10-800 RPM |

Specifications subject to change without notice.