PRODUCTS

AES Rocking Bioreactor System

Easily integrated single-use rocking bioreactor system for a wide range of cell culture applications.

The AES Rocking Bioreactor System provides an automated, controlled environment for the expansion of cell culture production in research, product development, and commercial operations. The flexible system accommodates any brand single-use cell culture bag and features open-source automation and control software that is easily managed via an intuitive user interface.

System benefits

- Exceptional flexbility and reliable results for

– Seed culture

– Batch refeed

– Perfusion

– In-stage batch and fed-batch operation - Designed for single-use bags, minimizing risk of sample contamination

- Accepts Corning® consumable solutions or can be modified to use other single-use bags

- By using common industrial protocols, easily integrate and leverage DeltaV and Rockwell platforms

- Take control of updates and application changes – without experts or costly additions

- Customize workflows and reports – on your own

- Two configurable pumps for perfusion, feeding,or pH control

- Temperature wave motion controls agitation for optimized cell culture environment – achieve high cell densities

- Variable agitation angle and rate allows you to adjust the mixing characteristics of the system to meet your application requirements

- 3 gas MFC control enables adjustment of the gas environment inside the reactor to suit your application needs

- Small instrument footprint maximizes work space

- Exchangeable trays in a variety of sizes expands application possibilities

- Suitable for GMP/GLP applications

- Overview

- Tech Specs

- Literature

System benefits

The system creates the ideal controlled environment for achieving high cell densities across a wide range of cell culture applications, such as the production of bacterial and mammalian cell line systems. The standard 25L platform can be used for solera, seed train, perfusion, or N stage batch and fed-batch operations, while the integrated dual pump system allows for additions or harvests. The rocker platform is also flexible, with optional trays to fit 10L and 50L bag sizes. If the standard rocker configuration does not meet your exact process requirements, our team of expert engineers will custom design and/or configure a solution tailored to your unique needs.

Do more – with less space, and less effort

The streamlined dual-pump instrument design saves you valuable work space. An industrial control layer enables remote monitoring and control wherever network access is available— and the rocker’s intuitive, user-friendly software makes process monitoring and system updates a breeze.

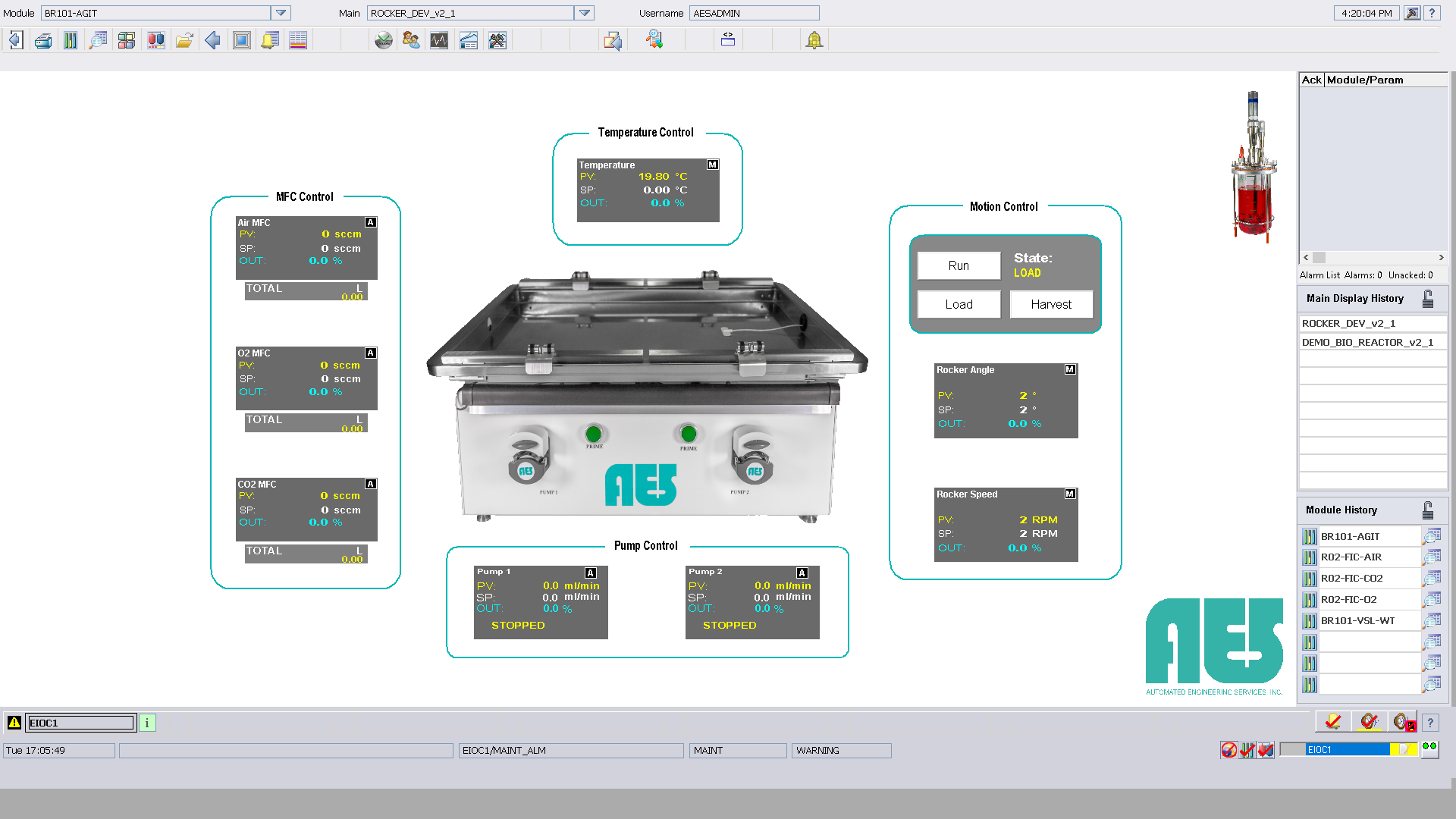

Intuitive user interface for easy management and control of all processes running on the rocker

Flexible design that’s GMP compliant

The modular system control enables easy integration into an existing distributed control system (DCS) or as the start for a new site DCS. Remote access to online adjustments, historization and system information is readily available through a networked computer or local HMI. All control hardware and software are 21 CFR Part 11, GMP/GLP and ISA88 compliant to satisfy regulatory requirements.

Take complete control of your process, or leave it to us. The choice is yours.

Our expert engineers provide the support you need with system integration and automation. Transparent, open source code is used for all control functions, giving YOU the ability to take control of updates as your application needs change. If you prefer, AES technical experts will continue to support your requirements and are available for on-site support within 24 to 48 hours at most continental U.S. locations.

System Specifications* (25L)

| Max culture volume | 25L |

| Cell culture bag | Choose your preferred brand |

| Heat control | Single-sided, heating blanket |

| pH control | Available |

| DO control | Available |

| Pump control | 2x integrated pumps for additions and harvest |

| Gas control | 3x MFCs |

Control

| DCS | Emerson DeltaV or Rockwell PLC |

| Hardware protocol | DeviceNet or Profibus (others available upon request) |

| Interface | Windows®-based PC or HMI |

| Software standard | ISA 88 |

Process Instrumentation

| Temperature probe | PT100 RTD, surface mount |

| Heat source | Relay controlled heating jacket |

| O2 | Brooks 2000 sccm |

| Mixed Air | Brooks 2000 sccm |

| CO2 | Brooks 2000 sccm |

| Agitation | Servo motor controlled |

| Integrated pumps | 2x Cole-Parmer Peristaltic |

| Hardware protocol | DeviceNet or Profibus (others available upon request) |

| Interface | Windows®-based PC or HMI |

| Software standard | ISA 88 |

Optional Instrumentation

| Load cell | Hardy |

| pH probe | Presens |

| DO probe | Presens |

| External pumps | Cole-Parmer Peristaltic |